Prototype excavator harvests helium-3 from the Moon

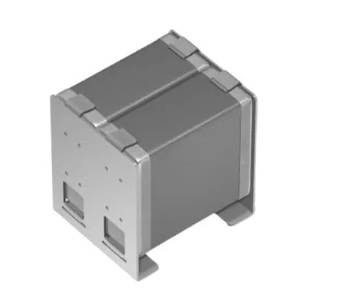

Natural resources company Interlune and industrial equipment manufacturer Vermeer Corporation unveiled the full-scale prototype of the Interlune excavator, a machine designed to ingest 100 metric tonnes of Moon dirt, or regolith, per hour and return it to the surface in a continuous motion. Interlune’s immediate focus is harvesting helium-3 from the Moon.

“When you’re operating equipment on the Moon, reliability and performance standards are at a new level,” said Rob Meyerson, Interlune Co-Founder and CEO. “Vermeer has a legacy of innovation and excellence that started more than 75 years ago, which makes them the ideal partner for Interlune.”

The excavator is the first product resulting from this joint development agreement; the companies will continue to explore other novel equipment and technology for use in space and on Earth. Vermeer CEO Jason Andringa will join the Interlune advisory board, bringing decades of experience in engineering and leadership in a global organisation.

“Vermeer innovation has always been about finding better ways to do important work and this project is no different. Combining my personal passion for aeronautics and astronautics with Vermeer equipment that bears my grandfather’s name to carefully and responsibly harvest resources to make our world a better place is something I’m incredibly proud of,” said Andringa.

Founded by Gary Vermeer in 1948, Vermeer Corporation is now led by his grandson Jason Andringa. With more than 280 products serving 10 diverse markets, Vermeer equipment helps feed and fuel communities, manage natural resources and connect people to daily necessities around the world.

“The high-rate excavation needed to harvest helium-3 from the Moon in large quantities has never been attempted before, let alone with high efficiency,” said Gary Lai, Interlune Co-Founder and CTO. “Vermeer’s response to such an ambitious assignment was to move fast. We’ve been very pleased with the results of the test program to date and look forward to the next phase of development.”

Excavation is the first in a four-step proprietary system to harvest natural resources from space: Excavate, Sort, Extract, and Separate. The Interlune excavator operates continuously and its design reduces tractive force, power consumption, and dust compared to traditional trench-digging techniques. Interlune and Vermeer built the full-size prototype after successfully developing and testing a sub-scale version in the summer of 2024.

The excavator prototype and partnership agreement with Vermeer marks a key milestone in developing the Interlune harvesting system. Interlune is actively testing other technology components, including several tests of its sorting and extraction devices in simulated lunar gravity on parabolic flights over the past year. The company develops and tests its proprietary separation technology at its cryogenic lab at the company’s Seattle headquarters.

Helium-3, a stable isotope of helium, is extremely scarce on Earth but abundant on the Moon. Government and industry have been looking for a new and scalable source of helium-3 since the US government identified a severe shortage around 2010.

There is tremendous demand for helium-3 across several industries, including national security, quantum computing, medical imaging, and fusion energy. Interlune aims to be the first company to commercialise natural resources from space, starting with Helium-3 from the Moon, which it will sell to commercial and government customers.

In 2024, Interlune received individual grants from the US Department of Energy and NASA TechFlights to advance proprietary separation and extraction technologies, respectively. In 2023, the company received a National Science Foundation (NSF) Small Business Innovation Research (SBIR) Phase I award to develop technology to size and sort lunar regolith. Interlune has raised $18 million in funding to date and is planning several missions to the Moon later this decade.