VTT new sensor system to improve road safety

VTT’s new sensor system helps to stop traffic accidents and improves the productivity of the mining industry. The solution is part of wider efforts where reliable sensors are created for challenging environments and extreme weather conditions.

Exceptional weather conditions such as thick fog, heavy rain, and snow storms, cause significant safety risks and costs in the transport and mining industries every year. VTT Technical Research Centre of Finland and Indian industrial engineering company Tooltech have subsequently developed a new environmental monitoring system that enables detecting obstacles efficiently in extremely poor to almost no visibility.

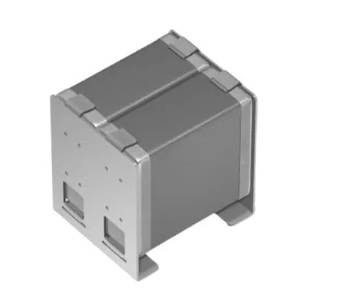

Comprising software and a sensing box device installed onto the front of the train, the new sensor system combines radar, thermal camera, satellite positioning, and AI. The system can detect humans and animals from more than 200 metres (more than 218 yards) and signal the driver of the vehicle instantly.

The technology has been tested with promising results on the railroads of India that people and animals, like dogs, cows, and elephants, often encounter. Collisions are commonplace and trains can travel safely in the foggy conditions of January–March only at 20 km/h.

According to test results, the technology allows the trains to significantly increase their speed safely while simultaneously decreasing the number of accidents. The system is currently undergoing evaluation at The Automotive Research Association of India (ARAI). The end user of the system will be Indian Railways, the railway company owned by the state of India.

“The test results in India show that the technology delivers a dramatic improvement to safety. There is also potential for applying the technology in Europe and the United States. For example, Germany and California experience up to a hundred foggy days a year,” said Matti Kutila, Research Team Leader at VTT.

The sensor system can also be used in the mining industry where unplanned operational shutdowns caused by weather conditions cause major financial losses. The technology helps to decrease the number of standstills by making work in extreme conditions safer.

“The sensor system improves the productivity of the work machines and improves safety. As the number of unplanned shutdowns decreases, capacity utilisation of the machinery goes up and production volumes increase. This affects the bottom line of the mines directly,” added Atul Khanna, Director of Tooltech.

The sensor system developed for India is part of VTT’s work to create reliable sensor solutions for challenging environments and extreme weather conditions. VTT and Tooltech Europe intend to export the technology to other developing markets.