Yokogawa unveils high-speed data acquisition unit

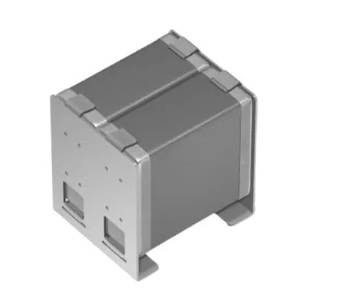

The SL2000 High-Speed Data Acquisition Unit, is a ScopeCorder series product from Yokogawa Test & Measurement.

It brings a wide range of data logging functionalities for evaluation and test applications, including high-speed sampling and analysis.

The SL2000 is a modular platform that combines the functions of a mixed signal oscilloscope and a data acquisition recorder, and is designed to capture fast signal transients and long-term trends. It is suitable for applications such as R&D, validation, and troubleshooting.

Depending on the application, the unit can be used separately or in combination with Yokogawa’s DL950 ScopeCorder, depending on the application. No other product family on the market offers this level of flexibility in handling multi-channel measurements. With the ScopeCorder product family, Yokogawa provides a multifaceted, total solution for the high-precision mechatronics and electric power markets that is contributing to the advancement and development of new technologies and applications.

This DAQystemenablesboth high-speed sampling and multi-channel measurement. It performs long-duration multi-channel measurements while precisely analyzing even the most detailed aspects of waveforms.

With its dual capture function, the SL2000 can perform measurements over long periods of time at speeds of up to 200 MS/s. And in situations where post-processing is required on a PC following measurement, the main unit can continue to perform measurements and has a function that allows calculations to be performed in real time.

This shrinks takt time – the calculated pace at which completed units must come off the production line.

By using the integrated measurement software IS8000, it is easier to perform the long-term measurements required for durability testing, helping to improve the efficiency of product design and evaluation work. In addition, isolation measurement technology ensures the noise resistance required for durability testing in harsh environments.

The SL2000 supports simultaneous measurement of a wide variety of devices. It has eight available slots (with up to 32 channels), for which over 20 types of input modules are available to enable measurements of electrical signals, mechanical performance parameters indicated by sensors, and decoded vehicle serial bus signals.

Michael Rietvelt, European Product Managaer at Yokogawa Test and measurement explains, “The SL2000 can undertake precise measurement of fast switching signals in the harshest of environments. The housing for the input modules includes both shielding for the single input channel and extra shielding for the housing of the input module. Using this double shielding method with the input channels inside the input modules results in high noise rejection and low channel interference.”

”With the IS8000 software the SL2000 is designed to be remotely operated,” he adds.

To increase the number of measurement channels, up to five SL2000 and DL950 units can be synchronized.

Major target markets are transportation (automotive, rail, aviation, etc.), power and energy (renewable energy, smart cities/homes, data centres, etc.) and mechatronics, including industrial robots and motors.

Applications

- Durability and reliability testing of components and vehicles that requires high sampling rates and multi-channel simultaneous measurement of analog signals and in-vehicle bus signals such as CAN and CAN FD.

- Simultaneous measurement and evaluation of temperature, vibration, and other mechanical signals that change relatively slowly as well as mechatronic and other such high-speed control signals.

- Electrical analysis and control signal evaluation.

Yokogawa says that in the four years since the DL950 ScopeCorder, there have been many technical advances in the electric vehicle (EV), renewable energy, and other industrial fields. Beginning the development of the SL2000 the company studied the market and canvassed the views of customers and noted that today, there is an ever-greater requirement for the capability to simultaneously measure multiple parameters and for the systemization of mechatronic measurements in product development.

For example, in the development of motors for industrial and EV systems, one essential test for checking and improving a product is the durability test. This test takes a long time to complete and requires a highly reliable measuring instrument and high sampling rates.